|

|

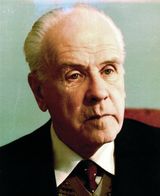

K.V. Kochnev

Doctor of Engineering, prof(1893 - 1977)

|

|

|

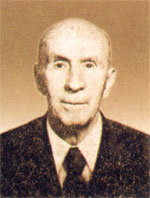

M.L. Rudakov

Doctor of Engineering, prof(1912 - 1964)

|

|

|

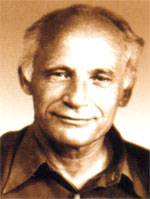

M.V. Vasiljev

Doctor of Engineering, prof(1903 - 1986)

|

|

|

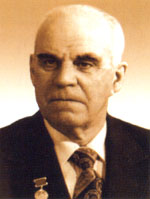

V.A. Shchelkanov

Doctor of Engineering, prof(1929 - 2004)

|

|

|

B.V. Faddeev

Doctor of Engineering, prof

(1910 - 1985)

|

|

|

A.N. Shilin

Doctor of Engineering, prof

(1911 - 1987)

|

|

|

V.P. Smirnov

Doctor of Engineering, prof

(1940 - 2005)

|

|

|

S.L. Fesenko

Doctor of Engineering

(1936 - 2002)

|

In 1963, as a result of ongoing reforms of the time, the Institute of Mining Engineering, along with other scientific institutes, was removed from structure of USSR Academy of Sciences and imparted into subordinate of State Committee on Coordination, later – on ferrous and non-ferrous metallurgy, then, after its reorganization – into subordinate of Ministry of Iron and Steel Industry. By this time the institute had highly qualified academic body, considerable scientific capacity and wide experience of conducting researches in the field of mining – these factors made a solid basis for ensuing fast development under the guidance of Ministry of Iron and Steel Industry (MISI) of USSR.

Years 1963-1964 had seen creation of laboratories of: open-cut transport (M.V. Vasiljev), surface mining technologies (A.N. Shilin), drilling of wells (I.N. Sidorov), mechanization of mining works (B.V. Faddeev), excavation and stacking (V.S. Plygunov, E.P. Doronenko), mechanization of supportive processes (A.P. Derjagin), automatics and teleautomatic (V.P. Kruckov), ventilation of open pits (S.S. Filatov), combined working of a deposit (V.A. Shchelkanov), economics (Y.I. Zhernakov).

Considerable help in the Institute’s development was given by administrative apparatus of MISI USSR, headed by P.E. Sledzjuk. The Institute of Mining Engineering of USSR Ministry of Iron and Steel Industry (IME USSR MISI) became the central, and as a lead executed functions of premiere in the branch in scientific directions: technology and complex mechanization of surface mining of iron and chrome ores, open-cut transport; technology and mechanization of drilling and blasting operations, protection of land resources, natural features and constructions; mined-land reclamation, electric equipment and power supply of open pits. Conducting a large amount of independent investigations, the institute simultaneously coordinated investigations of research institutes, engineering companies of mining profile of MISI USSR, many universities, institutes of Academy of Sciences of USSR and other offices.

The Institute, being the central and the lead in its branch, had to complete the following tasks:

1. improving of existing and searching for new, more advanced, technologies of surface and underground mining of commercial minerals at achieved and deeper levels and also under conditions of newly discovered deposits.

2. improving and further development of complex mechanization and automatisation of industrial processes in mining industry.

3. investigating the patterns of breaking ores, coals and rocks in course of mining commercial minerals on the basis for latest achievements in modern physics, chemistry, mechanics.

4. managing rock pressure and rock movement.

5. providing normal sanitary-hygienic labour conditions of miners in gas, temperature and dust characteristics of mines and deposits.

The whole amount of the Institute’s staff during subordinacy to MISI USSR reached 480 people, including 260 scientific workers, 11 of them doctors and 90 – candidates.

Scientific schools. In the process of solving branch problems, scientific schools had formed themselves in the Institute: of open-cut transport, founded by M.V. Vasiljev and V.L. Yakovlev, Ural school of geomechanics, founded by N.P. Vloh and A.D. Sashourin, school of quality control of ores, founded by P.P. Bastan.

The school of open-cut transport, widely known and recognized not only in the sphere of science, but also at mining enterprises in our country and abroad, was created and developed at the first stage by M.V. Vasiljev. Later it was headed by V.L. Yakovlev. Active organizers and participants of investigations in the field of open-cut transport were B.V. Faddeev, A.N. Shilin, A.N. Subbotin, E.P. Doronenko, B.V. Yakovenko, V.S. Volotkovskij, S.L. Fesenko, V.P. Smirnov, A.A. Kudrjavcev, Y.I. Lell, E.S. Kosnarev, G.D. Karmaev, V.B. Demkin, A.A. Kotyashev, A.P. Tulkin, P.I. Tarasov, Z.A. Ajurzanajn and others.

The main activity of the school is aimed at investigating problems of automobile transport; creating cyclical-and-continuous method of working rocky heads and hard rocks, theoretical justification for new generations of more productive mining transport equipment; defining patterns of forming of open pit area in mutual connection with development of schemes of transport communications.

In community with academic and branch research institutes, universities, engineering companies and machine building organizations, the Institute had created advanced and highly efficient cyclical-and-continuous method for surface mining of raw materials.

17 ore and fluxing open pits in the country were recommended to converse into cyclical-and-continuous method. Cyclical-and-continuous method and equipment were tested at experimental industrial points, constructed on in the open pits of Turgojakskoe Mining Group, Gaiskij, Kachkanarskij and Central Ore-mining and dressing plants. A range of works were done to justify characteristics and conditions of applying cyclical-and-continuous method at open pits of Kostomukshskij ore-mining and dressing plant, Karagajskij open pit of “Magnesit” complex plant, Kacharskij open pit.

For supplying cyclical-and-continuous method with new equipment, the Institute, in collaboration with machine-building organizations, has created self-propelled crushing units, with output 300-1000 ton/hour (SPC-1000, SPCU-3), uphill shakers, spreaders, and supporting equipment for conveyors. Together with engineering institutes Institute of Projecting Ore Enterprises and Institute of Projecting Ore Enterprises (South department) basis requirements for creating cyclical-and-continuous complexes with output 2000 and 4000 m3/hour were developed.

The Institute, in collaboration with Research Institute of Rubber Industry, has created conveyor belts on the basis for material MK-499/120, meant for transporting hard rocks, and comparable in strength to the best foreign samples. The developed belts are now produced by Ekaterinburg Plant of Mechanical Rubber Goods.(B.V. Faddeev, V.S. Volotkovskij).

Considerable merit in developing and implementation of cyclical-and-continuous method at open pits of MISI USSR belongs to M.V. Vasiljev, A.N. Shilin, B.V. Faddeev and many other scientists of the Institute. For participation in developing and industrial exploration of new progressive cyclical-and-continuous method, M.V. Vasiljev was awarded the USSR State Prize in 1984.

The institute has also become a country’s recognized scientific centre in investigating problems of automobile transport in open pits. Almost all new models of soviet and foreign dump trucks with carrying capacity 30-180 tons were tested with participation of its members at a number of big enterprises in the country: Sokolovsko-Sarbajskij ore-mining and dressing plant, Inguletskij Ore-Mining and Dressing Plant, Donskoj Ore-Mining and Dressing Plant, Severhyj Ore-Mining and Dressing Plant, Bashkirsij Copper-Sulphide Plant (BMSK), Gaiskij ore-mining and dressing plant, “Pechenganikel” complex plant, Priozerskij and Zaslavskij complex plants. Main models of perspective open-pit dump trucks BelAZ-7519(110 tons) and BelAZ -7521(180 tons) in development were brought to technical-and-economic standards and realized in series-production.

|

|

Dump truck

BelAZ-7521

|

Works of branch and inter-branch significance were completed, which define efficient conditions and operating conditions for dump trucks with carrying capacity 27-180 tons as in independent, main usage, so in complex transport schemes (M.V. Vasiljev, V.P. Smirnov, V.L. Yakovlev). analogous works were accomplished for foreign dump trucks M-120 (108 tons) by "Unit RIG" (USA), 120V (108 tons) by "Vabko" (USA), HD-1200 (120 tons) by "Komatsu"(Japan) and others.

For the first time the patterns of adhesion of automobile wheels with pavement surfacing of open pit automobile roads were experimentally defined; standard materials were created for fuel and lubricants consumption, for output norms of rock mass transporting and other, which grasp almost entire range of operating conditions of open pit transport.

In 60th-70th the Institute had solved a set of problems, connected with implementing down grade of 60 % in open pits, with conducting theoretical and experimental investigations in creating new brake equipment, providing engineering feasibility of increased incline in open pits. Scientific developments were made for constructing special open pit track maintaining equipment. On the basis for developed scientific-and-technologic standards track machine PRM-3 is produced in series since 1976. on the database of exploiting these machines, terms of references and technical propositions for constructing multifunctional track maintaining machine PRM-4 were made. The machine has successfully passed tests and was consigned for series-production. (A.P. Derjagin, B.K. Putyatin).

|

|

Track maintaining machine PRM-3

|

The most significant results in problems of optimization of transport systems include creating methodic of choosing type of transport, which was approved by MISI USSR. On its basis rational process schemes of transport were set in open pits of Olenegorskoe, Severnoe, Krivorozhskoe, Stoilenskoe, Korshunovskoe, Kachkanarskoe, Dneprovskoe ore-mining and dressing iron and steel industry plants, “Uralasbest” complex plant, a number of open pits in coal industry and non-ferrous metallurgy. Under development there is a Theory of systematic forming of transport systems in deep ore open pits, including methods of optimization of characteristics of transport schemes, taking into account mining-and-technical condition, changing in the process of exploitation.

|

|

N.P. Vlokh

Doctor of Engineering, prof.

(1924 - 1999)

|

The school of geomechanics, headed by N.P. Vlokh, later A.D. Sashourin, made invaluable contribution in development of geomechanics of rocks. methods of investigating strained state of rock mass, created in the Institute, already at the initial state had found wide application in a number of institutes and organizations in USSR. In particular, in 1972-1981 members of the Institute by the invitation of the institute “Hydroproject” held investigations on defining stress changes in bedrock of the world’s highest curved dam at Inguri Hydro-electric power station (Western Georgia).

With deep mining works passing on deeper horizons, the problem of preventing rock bumps sharpened, and in 1975 the Institute joined the solving of these problem at all iron-ore mines of Ural and Siberia. Timely forecast and measures, preventing rock-bump hazards, designed on geomechanical basis, allowed to cut the material loss and breakdown rate at mines to minimum.

One of the important problems for mines in 1960th-1970th was backfilling during extraction of massive ore bodies. Created in IME MISI USSR, the method of natural controllable caving of backs allowed mines to abandon forced extraction of goaf, provided the safety of mining works and brought considerable economic result.

Spread of the methodology of investigating rock pressure on rock movement processes in underground and surface mining, in combination with large volumes of instrumental measurement of shifts at ore deposits allowed to find out correlation between characteristics of deformation of rock mass in shift trough and edges of open-pit mines with initial strained state. The patterns found composed basis for essentially new concept and theory of movement process, usage of which provided a wide implementation of progressive solutions about construction protection and optimization of characteristics of edges of open-pit mines at mines in Ural and Kazakhstan, rational subsurface use through new completion of part of ore reserves of protective pillars, distribution of overburden in caving zones.

Field-proven theoretical assumptions were used in Rules of protecting constructions and natural objects against harmful effect of underground working at ferrous metal ore deposits in Ural and Kazakhstan, acting as standard document.

A new approach to creating geomechanical model of rock mass mined area required new means of measurement and techniques of assessing stressed state. Instead of minor bases of measuring stress, sized from several centimeters to first tens of meter, new method of measuring stress was created, applied at large bases, reaching 1.5 – 2 kilometers. This method was used to measure stress at 6 deposits, and works are conducted to interpret experimental data on 25-30 deposits, which make a serious contribution in learning the stressed condition of rock mass in Ural region and Earth’s upper crust on the whole.

As a result of investigation, made under guidance of V.G. Zoteev, theoretical justification was given to mechanism of hard rock slopes’ deformation in deep and ultradeep open pits; analytical solution of space problem of stability of slope with two and three surfaces of loosening was retrieved; methodic of calculating unloading area’s characteristics in rock mass, surrounding borrow cut; the patterns of creeping of dump sub-panels were defined; methodic of choosing technology and overburden dumping modes was developed. Results of researches were implemented at many enterprises in our country and neighbouring countries: “Korshunovskij More mining and Dressing Plant” JSC, “Kachkanarskij Ore-Mining and Dressing Plant “Vanadium” JSC, “Orenburgskije Mineraly” JSC, “Uralasbest” JSC, “Olenegorskij Ore-mining and Dressing Plant” JSC, “Kovdorskij Ore-Mining and Dressing Plant” JSC, “Sokolovsko-Sarbayskoe State Industrial Association” SC and others.

The school of geomechanics’ scientific achievements depended mostly on contribution of individual scientists To such scientists belong N.P. Vloh, A.D. Sashourin, A.V. Zubkov, V.G. Zoteev, V.E. Bolikov, Y.P. Shupletsov, Y.I. Lipin, O.V. Zoteev, V.P. Lelikov, S.M. Ushkov, Y.G. Feklistov, V.I. Doroshenko and others. For participation in creating scientific basis, developing and implementing measures of preventing and fighting landslide phenomena in sections and open pits, V.G. Zoteev was awarded State Prize of USSR in 1982, and for participation in creating and implementing methods of management rock pressure during mining ore deposits N.P. Vloh was awarded State Prize of USSR in 1989.

|

|

P.P. Bastan

Doctor of Engineering, prof

(1922 - 2001)

|

Scientific school of ore quality management and rational subsurface use had formed in late 1960th under guidance of P.P. Bastan. The main direction of scientific investigations in this field was connected with analyses of raw materials base of mining enterprises in USSR non-ferrous metal industry, solution of theoretical problems of blending ore before dressing, development of standard documents and procedures on questions of completeness and quality of extraction of non-ferrous metals ores reserves.

On the basis for theoretical investigations of the school, technological schemes of ore dressing at open pits were developed, including specialized stores, quality control stations, screening transfer points, schemes of forming and unloading of stores, means of operation monitoring and raw materials quality management in production lines.

The school has first obtained scientific results, investigating process of segregating of ore material during overburden dump, blending granular material of different particle-size distribution (A.V. Galjanov, Y.V. Laptev).

|

|

L.E. Zubrilov

Doctor of Engineering, prof

(1906 - 2000)

|

Researches on underground mining of deposits were conducted under guidance of K.M. Charkviani, L.E. Zubrilov, B.M. Shulmin, O.V. Slavikovskij. Under the leadership of V.A. Shhelkanov a new scientific direction was created – surface-and-underground mining method. A new scientific method of system assessment of deposits with optimization of characteristics of surface and underground mining works within one enterprise was created.

The main paths of researches are directed at improving and creating new systems of mining and opening of deposits through application of main loading and transportation levels and complex mechanization of mining operations, including output, delivery and transportation of ore using new types of mining machines.

The results of the investigations were realized in projects of building Severopeschanskaya, Estjuninskaya, Magnesitovaya mines, mines of Donskoj Ore-mining and Dressing plant, Sokolovskij underground mine and deep levels .

For participation in researching and justifying directions of exploration of mineral raw materials base and technical re-equipping of underground mines and open pits, L.E. Zubrilov and M.V. Vasiljev were awarded the Prize of Soviet of Ministers of USSR in 1982.

|

Truck and trailers ASh-75

|

|

In 1986, the laboratory of support setting of mine workings and stowing materials was founded. Under guidance of V.E. Bolikov, the laboratory had worked out the scientific basis and instructions in choosing types and characteristics of support of galleries and chambered workings for mines of Ural-Kazakhstan region; a new approach to choosing point of shaft emplacement and support under difficult mining-and-geological conditions was developed; scientifically justified approach to providing stability of galleries and chambered workings was developed. These Developments were implemented at iron ore and chromite mines of Ural and Kazakhstan, at enterprises of Ministry of Average Machine-building. a considerable contribution was made by the laboratory at initial stage of building Sverdlovsk Metro service in construction of main line tunnels and building stations under difficult mining-and-geological conditions.

The institute had completed a large complex of works in improving existing technology of surface mining of iron ores, opening, mining methods, borders and regulations of mining operations for majority of projected and working enterprises, including Ore-mining and Dressing Plants Sokolovsko-Sarbayskiy, Kachkanarskij, Korshunovskiy, Donskoj, Olenegorskij, Kovdorskij, Kostomukshskij, Lebedinskij and Poltavskij (A.F. Tkachev, G.G. Sakantsev). Along with it, a number of works, significant for the branch, were accomplished by order of MISI, particularly development of Decree and order of accounting technical indexes and composing year program of ore-mining and dressing plants, which found wide use in practice of planning and organization of mining works at enterprises in the branch.

|

|

Drill-rig TRD-250MN

|

The institute achieved substantial successes in solving problems of hole-drilling (N.I. Sidorov, R.I. Sukhov, G.G. Fedorova, L.V. Mozhaev and others).

Theoretical and experimental investigations, analyses of drilling technique and technology at Russian and foreign enterprises were accomplished, technical-and-economical conditions were worked out, together with technical enquiry for constructing new types of highly productive drill-rigs of roller bit, percussive-rotary, flame-jet, joint, thermal-mechanical, blast hole drilling, and also new types of pneumatic impact tools, roller-bits, drilling-bits of high persistence and cushion subs by State Project and Research Institute of Ore-Dressing, Research and Project Institute of Mining and Dressing Machinery Manufacturing, All-Union Research and Project Institute of Mining Machinery Manufacturing. creating, industrial test, series-production and implementing tools TRD-250MN (since 1980 TRD-250 MNA-32), TRD-320, TTMD-2S, TRD-250K, TRD-200, TRD-190/260/60, SBU-125HL, “URAL-64”, SBU-125 resulted in technical re-equipment of open pits. Experimental and industrial test of drill-rigs was performed by the Institute’s members at ore-mining enterprises according to specially developed methodics in Ural (Kachkanarskij Ore-dressing and Mining Plant, Bakalskoe Mining Group), Krivbass (Severnij, Novo-Krivorozhskij Ore-Mining and Dressing plants), at Lebedinskij, Olenegorskij, Sokolovsko-Sarbaiskij, Korshunovskij and other ore-mining and dressing plants. Drill-rig TRD-320, all-purpose drill-rig TRD-190/250-60 for drilling deep holes in smooth-wall blasting and preliminary kerf-formation were tested.

|

|

V.M. Senuk

Doctor of Engineering, prof

(1927 - 1994)

|

|

|

S.S. Filatov

Doctor of Engineering, prof

(1932 - 1989)

|

In the field of rocks breaking (P.S. Danchev, I.S. Kuklin, G.N. Khruschshev, V.M. Senuk, Y.M. Puchkov, V.P. Vetluzhskih, A.S. Matorin, V.G. Shemenev, V.G. Kuznetsov, D.S. Shakhmatov and others), investigations were conducted to improve existing and search for new, more effective means of breaking rock mass by blasting with the aim of deriving mined rock of required particle-size distribution, allowing to increase significantly the output of mining-and-transport equipment. A special attention was paid to hard-shot grounds, representing the biggest difficulty for crushing.

As a result of experimental and theoretical investigations, technology of blasting hard-rocks was created, based on the principle of independent work of blasting charges.

Since 1968 the Institute leads intensive researches of new blasting agents’ efficiency, including granular and slurry explosives, researches of physic and explosive properties of new blasting agents and developing recommendations on their improving and implementing in industry.

Formula and technology of preparation slurry explosives at mining enterprises was developed. The Following blasting agents were tested in open pits: grammonites 79/21, 82/18, granitol, carbatol - and admission to permanent applying these BA was attained.

In collaboration with Research and Project Institute of Mining Machinery Manufacturing, test samples were developed and mix-pump engines MZ-ZB-12, MZ-ZBV, MZV-10, MZG-10, MZ-4V were created, which were successfully used at mining enterprises of Ural (Kachkanarskij Ore-mining and Dressing plant and Uralasbest) and Kazakhstan (Sokolovsko-Sarbajskij Ore-Mining and Dressing Plant).

Staff of laboratory of open pit ventilation under guidance of S.S. Filatov and M.M. Konorev had completed a huge volume of theoretical and experimental investigations in the field of open pit aerology and development efforts on construction tools for ventilating open pits. Several constructions of exit gas neitralizators, protected by certificates of authorship and patents, were developed and implemented at enterprises.

|

|

|

Fan layout AF -1А

|

|

|

|

Open pit fan sprinkler

NК-12КV-1М

|

For providing induced ventilation of dead zones and open pits, in collaboration with Research and Project institute of Mining Machinery Manufacturing, different types of fan layouts on basis for aircraft lifting propellers and main rotors were developed, created and tested: AF-1A, AF-14, AF-21. series production of auxiliary fans AF-1A was mastered at Perm Mining Equipment Plant.

On the basis for powerful turboprop engines NK-12MV, turbofans-irrigators NK-12KV-1M were constructed. With the use of these turbofans, systems of all-season dust- and gas suppression in atmosphere of Tselinnij and Priagrunskij complex plants. Creation of these systems allowed to solve important scientific-and-technical problem: normalization of composition of atmosphere in open pits at negative temperature.

Since 1975, under the leadership of E.P. Doronenko and G.M. Chajkina, the investigations on mined-land biological reclamation and ecologic aspects of land-use at mining enterprises are being conducted. The institute had become coordinating centre for scientific researches in reclamation, which are accomplished by the institutes of the branch. The assessment of land use and land reclamation in the branch was conducted annually, for this purpose methodological instructive regulations on land inventory and record of its use and reclamation were compiled and approved by MISI USSR, and were constantly renewed (1977. 1983, 1984, 1988).

|

|

E.P. Doronenko

Candidate of Sc

(1932 - 1986)

|

A significant work, completed with the participation of leading specialists of branch-wise institutes, presents itself as Methodological instructive regulations on development of projects of mined-land reclamation at ore-mining enterprises of MISI USSR, approved by the ministry in 1985. during the same period two state standards were developed and approved.

On requests of enterprises, the institute created method of reclamation of dust-forming surfaces of tailing dumps, based on the principle of minimum earthing under conditions of top soil deficit (or absence).

In 1985 E.P. Doronenko was honoured as laureate of USSR Council Of Ministers’ prize for development and implementation of highly efficient methods and process schemes of mined-land reclamation.

Researches at laboratory of ore-mining industry economics were directed at improving planning and intra-plant cost accounting. As a result of completed investigations, directions of improvement of self-supporting methods of management at mining enterprises were defined. Optimum power of ore-mining enterprises in system of iron ore dynamic balance of Ural-Kazakhstan region was justified. In different years Y.I. Zhernakov, A.I. Ustiantsev, A.A. Krenz, N.V. Martynov (heads), N.K. Kobylnikova, L.F. Madzhula, V.K. Vasiljev worked at the laboratory.

The laboratory of organization and management (N.L. Stakheev – head of the laboratory, V.L. Kazakova, N.V. Martynov, A.I. Isakov) conducted important investigations In field of improving management of ore-mining industry. The grounds of planning industrial processes at open pits were created and applied in branch procedure manuals on organization enterprise’s acting on weekly and daily time schedule.

The laboratory developed a unified system of lost time record and annual output ratio of mining transport equipment in branch open pits; criteria for assessing size and main production and function departments of ore-mining and dressing plants were offered; characteristics for assessment of management economical efficiency were recommended; the sequence of analyses of existing management structures and choosing measures for their improving was stated. The suggestions on improvement of management structures were realized in branch solutions on Mikhailovskiy, Lebedinskiy, Sokolovsko-Sarbayskiy, Kachkanarskij and other ore-mining and dressing plants.

A considerable amount of investigations was accomplished by the laboratory on privatization of complex plant “Uralasbest”, ore-mining and dressing plants Kachkanarskij and Korshunovskiy, and their transformation into stock companies. Packages of documents, designed for converting plants into joint-stock companies, received approval of territorial Property Management Committees and were approved by State Propert Committee of RF.

Investigations of laboratory of analyses and forecasting development of mining industry were aimed at creating and compilation of long-term forecast of development of ore-mining industry. The results of conducted investigations on forecasting ore-mining production promoted accomplishment of measures, purposed to renew and improve existing technique and technology, and also at labour and production management. “Code of indexes of mining enterprises of metallurgic industry work” was annually compiled at the laboratory. K.M. Shtukaturov, A.V. Soroka (heads of laboratory), V.B. Demkin, I.S. Kuklin and others worked successfully in the laboratory.

Since august, 1970, the laboratory of mathematical support and computing techniques was organized (head of the laboratory – V.M. Alenichev). The laboratory conducted works on creating mathematic support, software and computer programs for solving mining technical problems, research and widening the use of mathematic methods in mining engineering. The laboratory created informational and mathematical support for subsystem of operative planning( weekly-and-daily, daily) of mining operations at open pits, extracting several technological types of ore and using different kinds of transport; created complex of programs for random-statistical processing experimental evidence, including economic and technological.

During the period of subordinacy to MISI USSR, the Institute was successively headed by: professor M.V. Vasiljev, Doctor of Engineering (1962 – 1985), who made a big contribution to development of the Institute and establishing its prestige in scientific world; A.A. Kotyashev, Candidate of Science (Engineering) (1985-1992); A.D.Sashourin, Candidate of Science (Engineering) (1992-1995), who put a lot of strength and energy for returning the Institute into structure of Russian Academy of Sciences. Deputy directors through the whole history of the Institute were: M.L. Rudakov, V.A. Shhelkanov, Y.I. Zhernakov, V.A. Shestakov, A.K. Ryabov, K.M. Shtukaturov, I.S. Kuklin, E.P. Doronenko, A.S. Matorin, A.D. Sashourin, V.P. Lelikov, N.L. Staheev, V.E. Bolikov, A.V. Zubkov. as academic secretaries worked: V.A. Shhelkanov, K.M. Shtukaturov, A.F. Tkachev, N.L. Staheev, A.D. Sashourin, B.G. Kienko, A.A. Kotyashev, V.P. Lelikov, G.I. Voroshilin, G.G. Sakantsev.

The results of the Institute’s scientific researches were realized at more than 40 enterprises of MISI USSR, situated in north-west and central Russia, in Urals, Kazakhstan, Ukraine, Siberia. The most close contacts were established between Kachkanarskij, Sokolovsko-Sarbaiskij, Korshunovskij, Mikhailovskij, Olenegorskij, Kovdorskij, Donskoj, Vysokogorskij, Bakalskij and other mining-and-dressing complex plants and mining groups.

The Institute’s developments were widely used by engineering companies and development laboratories. The Institute kept creative contacts with more than 20 educational, research, design institutes. According to results of investigations, accomplished before 1995, more than 50 monographs, 3500 articles were published, including publications in foreign pres and magazines; 93 collections of scientific papers and reports of six All-Soviet Union conferences and more than 110 items of instructional and methodological materials were printed out; 67 developments were awarded 97 medals of USSR Exhibition of Economic Achievements; 662 certificates of authorship and patents were received, and 95 inventions were implemented.

Many institute workers were awarded medals and orders for contribution in development of mining science and industry, including Order of Lenin (I.N. Sidorov), Order of the Red Banner of Labour (M.V. Vasiljev, L.E. Zubrilov, I.S. Kuklin), the Order of Honour Pin (N.P. Vloh, M.V. Vasiljev), Order of Friendship (V.L. Yakovlev).

February, 24, 2007. the Institute of Mining, one of the leading and oldest research and scientific institutes in the field of mining engineering, celebrates its 45th anniversary.

February, 24, 2007. the Institute of Mining, one of the leading and oldest research and scientific institutes in the field of mining engineering, celebrates its 45th anniversary.

At the present day, the Institute is able to solve the most difficult academic and applied problems in exploring and exploiting deep-seated deposits of mineral raw materials with difficult mining-and-geological bedding conditions.

At the present day, the Institute is able to solve the most difficult academic and applied problems in exploring and exploiting deep-seated deposits of mineral raw materials with difficult mining-and-geological bedding conditions.