Reversion of the Institute into the UB of RAS. Dynamics of its development

The process of reorganization in the country had led to collapse of sectoral science. Central funding stopped. Mining enterprises, suffering privatization, cut the production volumes sharply and turned out to be bankrupt. The institute had almost no means of sustenance. During this hard period A.D. Sashourin was appointed director of the Institute. New directorate (V.P. Lelikov, N.L. Staheev, V.E. Bolikov, G.G. Sakantsev), with an active participation of Council of Work Collective, started to search ways of surviving for the institute. The problem had two solutions: the first was privatization, the second – reversion to Ural Branch of Russian Academy of Sciences . Taking into account the negative experience of branch-wise institutes, already privatized, the first option had to be rejected. According to the poll, it was decided to realize the second option.

The Sverdlovsk Region Administration welcomed conversion of the Institute to Ural Branch of Russian Academy of Sciences, having directed a petition to the Metallurgy Committee and Russian Federation Government.

Chairman of presidium of Ural Branch of Russian Academy of Sciences (UB of RAS), member of the academy of sciences, G.A. Mesyats and his deputy, member of academy of sciences, V.A. Koroteev supported the institute’s appeal without hesitations, guided by expediency of having fully specialized institute of Mining Engineering in the structure of UB of RAS. Supposition of accepting the Institute into the structure of Russian Academy of Sciences was met with approval by the President of the Academy, member of Academy of Science, Y.S. Osipov and academic secretary V.A. Zharikov, who, in spite of funding cuts, went to length of integration of the whole Institute into the Academy.

In 1994, by the order of Russian Federation Government, the Institute of Mining Engineering was again allotted in UB of RAS.

|

|

|

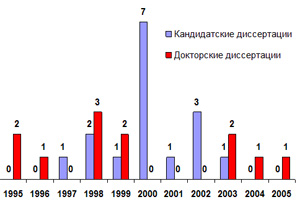

Динамика защиты диссертаций |

During the following 2-3 years the Institute had completely adapted in the system of the Academy, renewed and widened contractual links with many mining enterprises, won a range of RFFI grants, received necessary licenses for right to conduct a wide range of applied researches.

In 1995 the Institute was headed by corresponding member of Russian Academy of Sciences V.L. Yakovlev.

All the further period of the Institute’s activity in the structure of RAS is characterized by strengthening of cadre, improvement of funding, development of experimental base, fitting with modern research equipment, increasing the quality of basic researches and expansion of implementing works. The unique centre of geomechanical investigations was created and is now developing With financial support from RFFI. Vigorous activity of schools of open pit transport and rock mechanics is continued. The Institute of Mining Engineering of UB of RAS subsidiary in Chelyabinsk is founded.

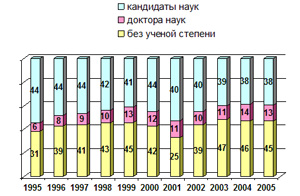

In the period 1993-2006 the cadre of Institute of Mining Engineering of UB of RAS has considerably improved, amount of Doctors of Science rose.

|

|

|

Динамика кадрового состава |

Almost all the specialists, who defended doctor’s and candidate’s dissertations, remained to work at the Institute. Due to this, the natural (age) loss of the Institute’s specialists was filled. Moreover, strengthening of highly qualified cadre was assisted by ceaseless improvement of the Institute’s financial position and growth in salaries.

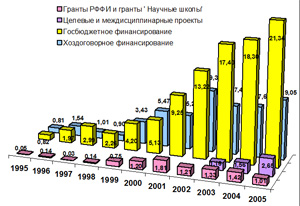

The main source of funding for the Institute are means of state-finance system, allotted by Ural Branch of RAS, and means, received for conducting works on the basis for commercial contract. RFFI grants and RF President’s grants, allotted to support leading scientific schools, target RAS programs, Earth Science Department of RAS and inter-disciplinary projects of regional RAS departments were and remain to be essential sources of funding.

Considerable part of means was spent on developing the experimental base – up to 10% of all incoming finances, what led to a significant rise in quality of basic researches.

Development of cadre and technical base changed the nature of investigations, conducted at the Institute.

Since 1998 the Institute conducted basic researches in scientific directions: development of theoretical grounds for technologies in complex exploration of mineral resources; geomechanical and ecological basis for interaction between natural and manmade objects of geosystem.

|

|

|

Динамика финансового обеспечения института |

Since 2001, by the order of Presidium of UD RAS, the scientific directions of the Institute were widened: developing theoretic grounds for exploration and complex exploiting mineral resources; creating basis for new technologies of mining deep-seated deposits; researching problems of geomechanic and rock breaking.

In the course of investigation on strategy of exploration and complex exploitation of mineral resources, the Institute has developed a conception of exploring Ural mineral resources. On this basis, the regional program “Ural Ore till 2005” was developed and approved by Sverdlovsk region administration in 1996, and “Conception of development of ore-mining enterprises of mining-metallurgy complex in Sverdlovsk region for the period to 2015” – in 2002.

Establishment of one whole dynamic system “mine-dressing fabric - metallurgical plant - waste-recycling workshop” was justified, within the framework of which theoretical and technical grounds were created for complex ore-dressing with precipitation of impurities as a standalone products. Complex of organizational and technological measures was developed, allowing to raise the efficiency of subsurface exploration through selective unloading of free-milling and complex ores and implementing combined schemes of raw materials recycling using hydrometallurgical processes, new reagents, synthesized by the Institute, of AIF type, electro pulse working up of raw materials, column flotators. According to the Institute’s developments, column flotator was produced at dressing fabric of Almatskij mining-metallurgical complex plant. Its implementation gave an opportunity to extract additional 200-600 tons of copper, 100-120 kilograms of gold, 400-500 kilograms of silver per year from current production tailings dumps, mainly on the account of recovery of fine grains of sulphides.

A large work is conducted in the Institute on quality control of iron ore raw materials at all stages of extraction and recycling.

In 2000, the Institute organized and held international Research and Practice conference “Modern methods and means of quality control and dressing of iron ore materials at all stages of recycling”, and in 2001, in collaboration with the Ural research institute of metrology and “Sreduralmetprom” – international coordination conference “modern methods and means of quality control of iron ore raw materials’.

Conceptual framework of applying surface geotechnology with inner dumping at exploitation of deep-seated deposits of little length was created at the Institute. Method of defining edges of deep open pits with account for risk was developed. In the process of experimental and industrial investigations, it was proven, that the main factors, influencing disturbance of peripheral mass during millisecond-delay blasting, are mass of charge in delay gear, direction of breaking and time of removal of bench share, falling at each peripheral charge. On the basis for this, sequence of priming was proposed, allowing to decrease mass disturbance by 5-8 times in comparison to traditional diagonal schemes. Technical and engineering solutions, aimed at efficient subsurface exploration, were prepared. Method, characteristics and economical efficiency of mining copper-sulphid were defined for deposits Jusinskoje and Barsuchij Log, Novoturinskoje touchstone deposit, Krutorozhskoje and Kvarkenskoje deposits of building materials. Efficient technology of production of benches in limit was realized at Kvarkenskiy open pit.

It was ascertained, that one of highly qualified technologies of underground mining under conditions of activity of tectonic forces is mining from bottom to top, which allows to eliminate or minimize the stress concentration in the mining region, raises stability of extraction chamber roof, excludes ore dilution by filling materials, provides possibility of placing burrow and dressing tailings in mined-out space.

Highly-efficient and safe technologies of underground extraction of commercial minerals under severe mining-and-geologic conditions were developed. Options for chamber mining with dry stowing of mined space under conditions of mine “Magnesitovaja” were offered. Project of mining ore body in 2 Uzelginskoje deposit was prepared. Recommendations were formulated on mining ledge Nizhnaja in Sibaiskoje deposit (using system of caving adjacent strata) and in underground mine at Gaiskoje copper-sulphide deposit.

|

|

|

Участники международного семинара "Основные направления создания и совершенствования |

The Institute pays much attention to raising efficiency of most labour-intensive technological processes of surface mining of mineral material deposits – drilling and blasting operations and rock mass transportation.

Patterns of rock breaking by combined shearing during roller drilling of blast holes were defined. Possibility of creating zones of advance rock loosening through redistribution of fracture load in face and their successive shearing was experimentally proven. industrial tests of roller bits, produced according to the projects of the Institute and possessing higher strength and drilling speed, were held At open pits of complex plant “Uralasbest”, Kachkanarskij ore-mining and dressing plant and India. In 2004, the Institute, in collaboration with Mining Group of Ural Mining and Metallurgic Company (UMMC), JSC “Uralburmash” held (with financial support from UMMC) international seminar “Main directions of creating and improving boring equipment and tools for borehole boring”. According to the decision, made by the participants of the seminar, Institute of Mining Engineering of UB of RAS is acknowledged to be the head organization with coordinating function in field of developing main directions of country’s boring tools and tools of up-to-date technical standard for hard rocks.

As a result of investigating properties of local rock masses, stable relations were found between mass property and its seismic characteristic. Inter-connection defined between mass’ resiliency to uniaxial compression and their bulk density and speed of p-wave in the mass. Patterns of explosion heat changes and volumetric energy of BA based on invert emissions were determined and new recipes of BA were developed.

A large amount of investigations was conducted, connected with development of simple and slurry BA, activation of blasthole charge, researching failure causes, developing and exploring technology of preparation and means of mechanization of blasthole loading with explosive composition. economic effect of replacing tolite with slurry explosives at Kachkanarskij Ore-mining and dressing plant comprises not less than 8 000 roubles per 1 ton. Implementation of the Institute’s recommendations at complex plant “Uralasbest” allowed to cut costs on recycling ammonium nitrate by 1.5 times, and in Orskoje open pit directory – to reduce amount of drilling operations by 20% and specific consumption of explosives by 10-15%.

Methodology of forming combined mode traction transport equipment was justified. Fields of efficient exploitation of existing open cut dump trucks with different unit power were distinguished. Optimal zones for applying special and purpose-designed vehicles – trolley cars, dump trucks with combined power plant, sinking complexes in combination with purpose-designed vehicles and excavation equipment were defined.

|

|

|

Президиум международного научно-технического семинара |

In 2003, in collaboration with production organization “BelAZ”, Ural State Mining University, JSC “Uralskiy turbomotornyi zavod”(Ural Plant of Turboengines), JSC “Uralhyproruda”, JSC “Pnevmostroymashina”, CJSC Scientific and Product Company “UVENK”, the Institute held international scientific-and-technical seminar “Saving energy on open pit automobile transport”. approximately 100 representatives of leading academic, branchwise and educational institutes, mining enterprises and plants, producing mining transport equipment from Uzbekistan, Kazakhstan, Belarus, Ukraine, Mongolia and Russia took part in the work of the seminar.

The Institute achieved significant successes in field of geodynamic. On the basis for exploration of stressed state of rock mass at 25 Ural deposits and definition of deformation of earth’s crust between groups of astrostations (using satellite navigation systems) it was determined, that Ural is not the linear structure. Technologies of satellite geodesy were adapted to tasks of current problems, methods and technologies of monitoring shifts and deformations or rock mass were generated, among other things, modes of continuous monitoring existent movements. Cumulative experimental data on deformation processes in mining area allowed to create geomechanical model of lithosphere section containing manmade object.

Dependence of changing strength and deformational properties of hard rock masses on their structural specifications, mode of changing of stressed state was found. Deformation model of hard rock mass was essentially worked out. Geomechanic model of tectonic disturbance was theoretically justified, on the basis for this model its geometric and power classification was generated and identity of forming centres of natural and manmade earthquakes was proven. Criteria of forming centres of rocky and tectonic bumps (manmade earthquakes) during mining commercial minerals were generated.

It was found, that one of factors, determining appearance and development of centres of manmade disasters, is represented by deformation processes, taking place in the rock mass of Earth’s upper crust in the zone of influence of mining industry.

Investigations on geomechanic supply of efficient and safe exploitation of deposits in Ural and some other mining regions of Russia and other CIS countries were accomplished:

- regulatory documents were prepared (“Instruction on support setting of mine workings and their face-ends at mines of Vysokogorskij ore-mining and dressing complex plant);

- geodynamic activity of rock mass and earth surface was explored (Donskoj ore-mining and dressing plant, Kazakhstan; building plots in Surgut; building plot of IV nuclear unit at Beloyarskaya APP; ore field of mine “Magnesitovaya” at Vysokogorskoje deposit);

- reasons of deformation of open pit’s edge at open pit ‘Glavnyj’ and pulp pump station 3 at Kachkanarskij ore-mining and dressing plant were found;

- control of development of movement process and state of objects under protection at mining ore reserves of protective pillar (mine ‘Ekspluatatsionnaya’, Vysokogorskij ore-mining and dressing plant);

- reasons for deformation of north edge of Korshunovskij open pit were found and measures on its stabilization were recommended;

- recommendations, agreed upon with research institute of geomechanics and mine surveying VNIMI, on safe conduction of extraction operations at mines of SC “Dalpolimetal”, rock-bump hazardous, were prepared.

Investigations, aimed at environmental engineering in commercial minerals mining, showed, that it is possible to decrease manmade influence on the environment in Ural mining areas not only through mined-land reclamation methods, but, under certain conditions, also due to unforced natural processes, efficiency of which is defined by geotechnology of selective mining and selective filling of potentially rich, and sometimes even of little avail, rocks within the bounds of recultivating layer.

For the first time, scientific basis for computing boundary layer of jet and fields of ventilation flows in surrounding atmosphere under open pit conditions. Digital models for defining characteristics of dust and gas cloud of potentially contaminated area. Optimal conditions of generating liquid and solid precipitations and spreading of air-vapor jets were established.

The Institute keeps close creative connections with many universities, academic and branchwise institutes of Russia, near and far abroad. Many Institute’s workers are lecturing at universities and colleges, supervise and review diploma and course projects, take part in activity of specialized councils on defense of doctor’s and candidate’s dissertations. The Institute organizes and holds international multi-profile conferences, seminars and other events, engaging a wide circle of specialists and organizations.

|

|

|

Мельниковские чтения в г.Екатеринбурге в 1998 г. |

In1998, in collaboration with Ural State Mining-and-geology Academy, the Institute organized and held international conference “Problems of geotechnology and subsurface learning”(Melnikovskije readings).

In 2006, in collaboration with Institute of Geology and Geochemistry of UB of RAS and exhibition centre KOSK “Russia”, the Institute organized Ural Mining Industry Forum, which included three scientific and technical conferences: “Geological exploration, monitoring state of deposits and new technologies of mineral raw materials reserves assessment”; “Mining equipment and resource-saving technologies of extracting and recycling mineral raw materials”, “Problems in creating environmentally safe mining industry. Safe subsurface management and environment engineering.” Moreover, the forum included panel discussion “Efficiency of investment projects and prepositions on exploring deposits of minerals at a current stage of society’s development”, business meeting “Systems of automated control of open pit transport”. also there was organized a inter-regional dedicated exhibition.

Solutions of conferences, seminars and sessions, held by the Institute, have a significant influence on direction of its investigations.

|

|

|

Уральский горнопромышленный форум в 2006 г. |

For high achievements in scientific work, a great number of the Institute’s workers are honoured with different awards. V.L. Yakolvlev is awarded with “Order of Honour” and “Yaroslav The Wise” order of II degree, he is the laureate of awards named after academician N.V. Melnikov and L.D. Shevjakov. Y.V. Volkov became a laureate of Russian Government Prize in science and technic, A.D. Sashourin was awarded the title “Honoured worker of science of Russian Federation”, V.E. Bolikov – title “Honoured builder of Russian Federation”.

A number of staff became laureates of Ural Mining Prize, Tatischev and V.I. Gennin Award, Efim and Miro Tcherepanovy award. Big number of members are awarded with pins “Honorary worker of fuel and energy sector” and “Honorary worker of coal industry” and other awards and honours.

|

|

|

Встреча с участниками и ветеранами войны в день 50-летия Победы над фашистской Германией |

Main menu

- Новости

- Об институте

- Структура

- Дирекция

- Научные подразделения

- Ученый совет

- Диссертационный совет

- Академия горных наук

- НП "Горнопромышленная ассоциация Урала"

- Совет молодых ученых

- Ведущие сотрудники

- НОЦ «Геотехнологии»

- Аспирантура

- Научная библиотека

- Профсоюзный комитет

- Инновации

- Конференции

- Проекты

- Издания

- Видео

- Вакансии

- About Us

Оценка результативности

- Во исполнение Распоряжения ФАНО России от 25.04.2017 № 111 и согласно письму ФАНО России от 04.05.2017 № 007-18.2-11/МК-138 о внеочередной оценке организациям, Институт горного дела УрО РАН предоставляет в ФАНО России сведения для экспертной оценки результатов деятельности за отчетный период (в приложенном файле в формате .pdf).

Новости науки CNews

- Когда и как водород попал на Землю? Крупнейший на планете резервуар — прямо у нас под носом

- Почему наступают ледниковые периоды? Ученые назначили козлом отпущения Марс

- Новое исследование показывает, что человеческий мозг работает на автопилоте две трети дня

- 14 000 лет назад волчонок съел кусок шерстистого носорога — это помогло раскрыть тайну вымирания гигантов ледникового периода

- Дирижабли поднимут квантовые центры обработки данных в стратосферу — зачем это нужно?